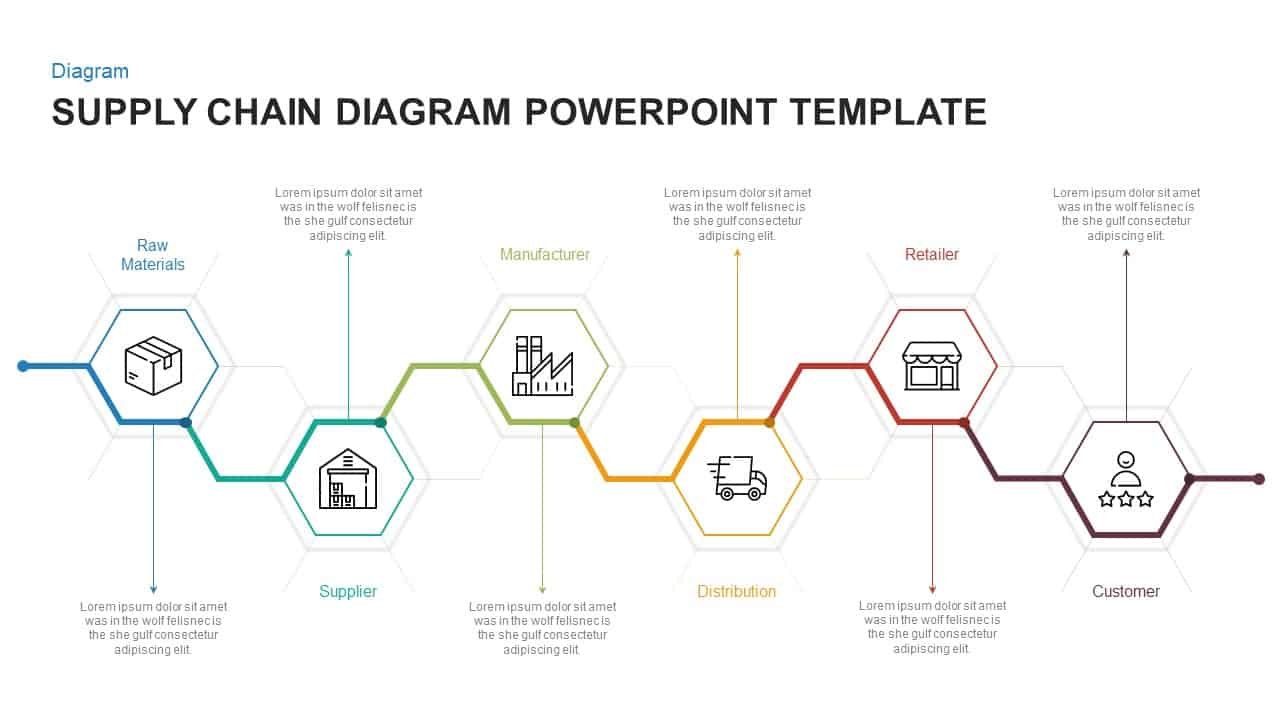

A Supply Chain Roadmap Template serves as a strategic tool for managing and optimizing supply chain processes. It outlines key activities, milestones, and goals to align supply chain operations with overall business objectives. By using a structured approach, businesses can enhance efficiency, reduce costs, and improve customer satisfaction.

Identifying the Essential Components:

-

Strategic Goals and Objectives

The foundation of this template includes clearly defined strategic goals and objectives. These goals align with the overall business strategy and provide direction for supply chain activities. Common objectives might include reducing lead times, improving delivery reliability, or increasing inventory turnover.

-

Key Features:

- Alignment with business strategy.

- Measurable and achievable goals.

- Specific timeframes for achieving objectives.

By setting clear goals, businesses can focus their efforts on key areas that drive value. This alignment ensures that supply chain activities support broader organizational objectives.

Related Article: Inventory Tracking Spreadsheet

-

Current State Analysis

Understanding the current state of the supply chain is crucial for developing an effective roadmap. This analysis involves evaluating existing processes, systems, and performance metrics. It helps identify strengths, weaknesses, opportunities, and threats.

-

Key Features:

- Detailed assessment of supply chain processes.

- Identification of key performance indicators (KPIs).

- SWOT analysis to identify areas for improvement.

A thorough current state analysis provides a baseline for measuring progress and identifying areas that require attention. It forms the foundation for developing targeted improvement initiatives.

-

Future State Vision

The supply chain roadmap template should include a vision of the desired future state. This vision outlines the target operating model, including process improvements, technology upgrades, and organizational changes.

-

Key Features:

- Clear description of the future operating model.

- Identification of required resources and capabilities.

- Roadmap for achieving the future state.

By defining a clear vision, businesses can create a strategic plan for transforming their supply chain. This future state vision serves as a guide for prioritizing initiatives and allocating resources.

-

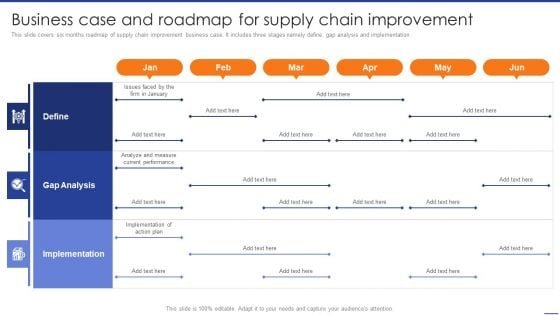

Gap Analysis

Gap analysis compares the current state with the future state vision to identify gaps and areas for improvement. This analysis helps prioritize initiatives and allocate resources effectively.

-

Key Features:

- Identification of gaps between current and future states.

- Prioritization of improvement initiatives.

- Resource allocation for addressing gaps.

Conducting a gap analysis ensures that efforts focus on high-impact areas. It provides a structured approach for addressing deficiencies and achieving the desired future state.

Related Article: Inventory Management Templates

-

Initiative Planning and Prioritization

Based on the gap analysis, businesses can identify specific initiatives to achieve their future state vision. These initiatives might include process improvements, technology implementations, or organizational changes.

-

Key Features:

- Detailed description of improvement initiatives.

- Prioritization is based on impact and feasibility.

- Timeline and resource allocation for each initiative.

Initiative planning ensures that efforts are focused and aligned with strategic goals. By prioritizing initiatives, businesses can achieve quick wins and build momentum for further improvements.

-

Implementation Plan

An implementation plan outlines the steps required to execute improvement initiatives. This plan includes detailed timelines, responsibilities, and resources needed for successful execution.

-

Key Features:

- Detailed action plans for each initiative.

- Assignment of responsibilities and accountability.

- Timeline and milestones for tracking progress.

A well-defined implementation plan ensures that initiatives are executed efficiently and effectively. It provides a clear roadmap for achieving the desired future state.

Related Article: Action Plan Template

-

Performance Monitoring and Metrics

Continuous monitoring and measurement are essential for assessing the effectiveness of supply chain initiatives. This involves tracking key performance indicators (KPIs) and comparing them against targets.

-

Key Features:

- Identification of relevant KPIs.

- Regular performance reviews and reporting.

- Continuous improvement based on performance data.

Performance monitoring ensures that supply chain activities remain aligned with strategic goals. It provides a basis for making data-driven decisions and identifying opportunities for further improvement.

Role in Project Management:

This template plays a critical role in project management by providing a structured approach for planning, executing, and monitoring supply chain initiatives. It ensures alignment with strategic goals, enhances communication, and improves decision-making.

- Alignment with Strategic Goals: By aligning supply chain activities with business objectives, the roadmap ensures that efforts contribute to overall organizational success. This alignment helps prioritize initiatives that drive the most value.

- Enhanced Communication: The roadmap provides a common framework for communication among stakeholders. It ensures that everyone understands the strategic direction, priorities, and progress of supply chain initiatives.

- Improved Decision-Making: The structured approach of a supply chain roadmap template supports data-driven decision-making. It provides a clear view of current performance, future goals, and the steps required to bridge gaps.

Defining the Key Benefits:

-

Improved Efficiency

By identifying and prioritizing improvement initiatives, a supply chain roadmap template helps streamline processes and eliminate inefficiencies. This leads to faster lead times, reduced costs, and improved productivity.

-

Cost Reduction

A structured approach to supply chain management helps identify cost-saving opportunities. By optimizing processes and reducing waste, businesses can achieve significant cost reductions.

Related Article: Product Roadmap Template

-

Enhanced Customer Satisfaction

Improved supply chain performance translates into better customer service. Faster delivery times, reliable order fulfillment, and higher product quality enhance customer satisfaction and loyalty.

-

Risk Mitigation

This effective template helps identify and mitigate risks. By proactively addressing potential issues, businesses can reduce the impact of disruptions and ensure continuity of supply.

-

Scalability and Flexibility

A well-defined supply chain roadmap provides a foundation for scaling operations. It ensures that processes and systems can adapt to changing business needs and market conditions.

-

Better Collaboration

The roadmap enhances collaboration among supply chain partners by providing a clear framework for communication and coordination. This leads to more effective partnerships and improved supply chain performance.

Related Article: Construction Project Management

Challenges in Implementation:

-

Resistance to Change

Implementing a supply chain roadmap often involves significant changes in processes, technology, and organizational structure. Resistance to change can hinder progress and impact the success of initiatives.

-

Resource Constraints

Limited resources, including budget, personnel, and technology, can constrain the implementation of supply chain initiatives. Effective resource allocation is crucial for overcoming these constraints.

-

Complexity of Supply Chain Networks

Modern supply chains are complex and involve multiple stakeholders, including suppliers, manufacturers, and logistics providers. Coordinating efforts across these stakeholders can be challenging.

-

Data Quality and Availability

Accurate and timely data is essential for effective supply chain management. Inconsistent or incomplete data can impact decision-making and hinder the success of improvement initiatives.

-

Technological Integration

Integrating new technologies with existing systems can be complex and time-consuming. Ensuring compatibility and seamless integration is crucial for successful implementation.

Related Article: Supply Chain – Wikipedia

Conclusion

A Supply Chain Roadmap Template is an essential tool for managing and optimizing supply chain processes. By using this template, businesses can navigate the complexities of supply chain management and achieve sustainable success.